Are you looking to take your small meat processing and packaging business to the next level? The meat industry is a difficult one to navigate, with stringent regulations, fluctuating demand, and intense competition. However, with the right strategy, it’s possible to scale up your business and position yourself for long-term success.

Understanding the Meat Processing and Packaging Industry

The meat industry is a complex ecosystem, involving a variety of players such as suppliers, processors, distributors, and retailers. The industry is responsible for processing and packaging meat products that will be sold to consumers in grocery stores, restaurants, and other food service establishments. Meat processing and packaging is a vital part of the food industry, providing a source of protein for millions of people around the world.

Before you can begin to scale your business, it’s important to have a grasp on the competitive landscape and industry trends. Understanding the key players and trends can help you make informed decisions about your business strategy and positioning.

Key industry players and trends

The meat processing and packaging industry is dominated by a handful of major players, such as Tyson Foods, JBS USA, and Cargill. These companies have massive economies of scale and significant purchasing power. However, there is still room for small businesses to carve out a niche in the industry by focusing on specialty products or localized distribution.

One trend that has emerged in recent years is the growing demand for organic and grass-fed meats. Consumers are increasingly concerned about the environmental and health impacts of traditional meat production, and are willing to pay a premium for sustainably produced meats. By positioning your business as a leader in this trend, you can tap into a growing market and differentiate yourself from larger competitors.

Another trend to be aware of is the increasing use of technology in meat processing and packaging. From automated cutting and packaging machines to sophisticated tracking and tracing systems, technology is transforming the way meat products are produced and distributed. Keeping up with these technological advancements can help your business stay competitive and efficient.

Regulations and certifications to consider

Meat processing is one of the most highly regulated industries in the United States, with numerous federal and state requirements to comply with. Some of the key regulations to be aware of include the Federal Meat Inspection Act, the Clean Water Act, and the Clean Air Act. It’s important to have a thorough understanding of these regulations and ensure that your business is in compliance.

Additionally, there are various certifications you may want to pursue, such as Organic, Humane, or Halal certifications, which can help distinguish your products and appeal to specific customer segments. These certifications require adherence to strict standards and can be a valuable marketing tool for your business.

In conclusion, the meat processing and packaging industry is a complex and dynamic ecosystem. Understanding the key players, trends, and regulations can help you make informed decisions about your business strategy and positioning. By staying up-to-date with industry developments and focusing on quality and sustainability, your business can thrive in this competitive market.

Assessing Your Current Business Operations

Before you can begin to scale your business, it’s important to have a clear understanding of your current production capacity, supply chain, and performance metrics. This will help you make informed decisions on how to improve your operations and increase your profitability.

Analyzing your production capacity

When analyzing your production capacity, it’s important to consider the amount of meat you can realistically process and package on a daily basis. This includes taking into account the size of your facility, the number of employees you have, and the equipment you use. It’s also important to identify any bottlenecks in your production line, such as slow machinery or inefficient processes, and find ways to address them. By optimizing your production capacity, you can increase your output and meet the demands of a growing customer base.

Evaluating your supply chain and sourcing

When evaluating your supply chain and sourcing, it’s important to consider where you currently source your meat from and whether there are opportunities to improve the quality or efficiency of your supply chain. This may involve finding new suppliers who can provide higher-quality meat at a lower cost, or streamlining your supply chain to reduce transportation and storage costs. Additionally, it’s important to have contingency plans in place in case of disruptions or shortages. This may involve maintaining relationships with multiple suppliers or having backup storage facilities.

Identifying areas for improvement

Identifying areas for improvement is essential to increasing your overall productivity and profitability. This may involve analyzing your performance metrics, such as your yield per animal or your waste reduction rate, to identify areas where you can make changes. For example, you may find that you’re producing too much waste during the butchering process, and can implement new techniques to reduce waste. You may also find that certain processes are redundant or unnecessary, and can be eliminated to increase efficiency.

By assessing your current business operations and identifying areas for improvement, you can make informed decisions on how to scale your business and increase your profitability. It’s important to regularly review your operations and make changes as needed to stay competitive in the market.

Developing a Growth Strategy

Once you have a clear understanding of your current operations, it’s time to begin developing a growth strategy that will take your business to the next level.

As you begin this process, it’s important to keep in mind that growth can take many forms. Some businesses may focus on expanding their product offerings, while others may look to target new markets or increase their volume output. Whatever approach you choose, it’s essential to set clear objectives and milestones to measure your progress and hold yourself accountable.

Setting Clear Objectives and Milestones

Before you can begin developing a growth strategy, you need to have a clear idea of what you want to achieve through scale. This may involve expanding your product offerings, targeting new markets, or increasing your volume output.

Once you’ve identified your goals, it’s important to set clear objectives and milestones that will help you measure your progress. This will allow you to track your success and make adjustments as needed to ensure that you stay on track.

Expanding Your Product Offerings

One approach to growth is to expand your product offerings. This may involve introducing new products or variations of existing products to your line.

Before you introduce any new products, it’s important to conduct thorough market research to ensure that there is demand for them. This may involve analyzing market trends, surveying customers, or conducting focus groups to gather feedback.

By expanding your product offerings, you can appeal to a broader range of customers and increase your revenue streams.

Targeting New Markets and Customer Segments

Another approach to growth is to target new markets or customer segments. This may involve expanding geographically or targeting specific demographic segments that align with your product offerings and branding.

Before you begin targeting new markets, it’s important to conduct research to ensure that there is demand for your products in those areas. This may involve analyzing demographic data, researching competitors, or conducting surveys to gather feedback from potential customers.

By targeting new markets and customer segments, you can increase your customer base and revenue streams, while also diversifying your business.

As you develop your growth strategy, it’s important to keep in mind that growth is a process that requires ongoing attention and adjustment. By setting clear objectives and milestones, expanding your product offerings, and targeting new markets and customer segments, you can position your business for long-term success.

Investing in Technology and Automation

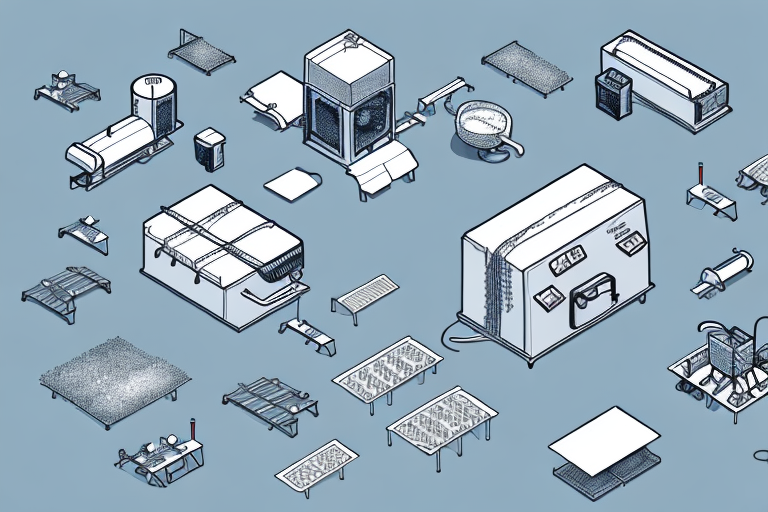

One of the keys to scaling your business in the meat processing and packaging industry is investing in technology and automation. By doing so, you can not only increase your production capacity, but also improve the quality of your products and reduce labor costs.

Benefits of automation in meat processing

Automating certain aspects of your production line can help reduce labor costs, increase efficiency, and improve product consistency. For example, using conveyors to transport meat from one part of the production line to another can save time and reduce the risk of contamination. Portion cutters can ensure that each piece of meat is the same size and weight, while vacuum packaging machines can extend the shelf life of your products and reduce waste.

Moreover, automation can also improve workplace safety by reducing the need for manual labor and minimizing the risk of injury. This can not only protect your employees but also reduce the likelihood of costly lawsuits and workers’ compensation claims.

Selecting the right equipment for your business

When selecting equipment for your business, it’s important to consider factors such as production volume, product type, and budget. For example, if you primarily process ground beef, you may want to invest in a grinder that can handle large quantities of meat quickly and efficiently. On the other hand, if you specialize in premium cuts of meat, you may want to invest in a precision slicer that can produce consistent slices of meat with minimal waste.

It’s also important to consider the long-term costs of the equipment, such as maintenance, repairs, and replacement parts. While it may be tempting to choose the cheapest option, investing in high-quality equipment that is built to last can save you money in the long run.

Implementing technology to improve efficiency

In addition to equipment, there are a variety of technologies you can implement to improve your operations. For example, inventory management software can help you keep track of your stock levels and reduce waste by ensuring that you always have the right amount of ingredients on hand. Temperature monitoring systems can help you maintain the quality and safety of your products by alerting you to any deviations from the optimal temperature range. Automated packaging systems can save time and reduce the risk of errors by automatically weighing, labeling, and sealing your products.

When implementing technology, it’s important to choose solutions that integrate seamlessly with your existing systems and processes. This can help you avoid disruptions to your operations and ensure that your employees can quickly adapt to the new technology.

In conclusion, investing in technology and automation can help your meat processing and packaging business improve efficiency, reduce costs, and increase profitability. By carefully selecting the right equipment and technology solutions, you can position your business for long-term success in a competitive industry.

Conclusion

Scaling a small business in the meat processing and packaging industry is no easy feat, but with a clear strategy and attention to detail, it can be done. Understanding the industry landscape, assessing your current operations, developing a growth strategy, and investing in technology are all key components to success. Keep in mind that scalability should not come at the cost of quality or sustainability – ensuring that your products meet customer demands and uphold regulatory standards should remain a key priority along the way.